By Emma Griffiths

Last December I embarked on a 12-month internship with AOC Archaeology, based in Edinburgh, and Go Industrial, a Scottish Charitable Incorporated Organisation that encompasses more than 14 different industrial heritage sites around the country.

The internship is made possible by Powering Our People, a project aimed at addressing the gap in conservation skills and specialist training within industrial heritage institutions across Scotland, by equipping workforces with the skills and resources to care for these nationally significant collections. This project is generously funded by a number of organisations, including the National Lottery Heritage Fund, Pilgrim Trust, and Museums Galleries Scotland.

Over the course of the last 9 months, I have been out to visit many of the Go Industrial sites, meeting staff and volunteers, getting a behind the scenes glimpse at the collections, and discussing the conservation needs of each institution. These have ranged from interventive treatments, to in house workshops and manuals to guide volunteers in the care of their collections, to advice on integrated pest management.

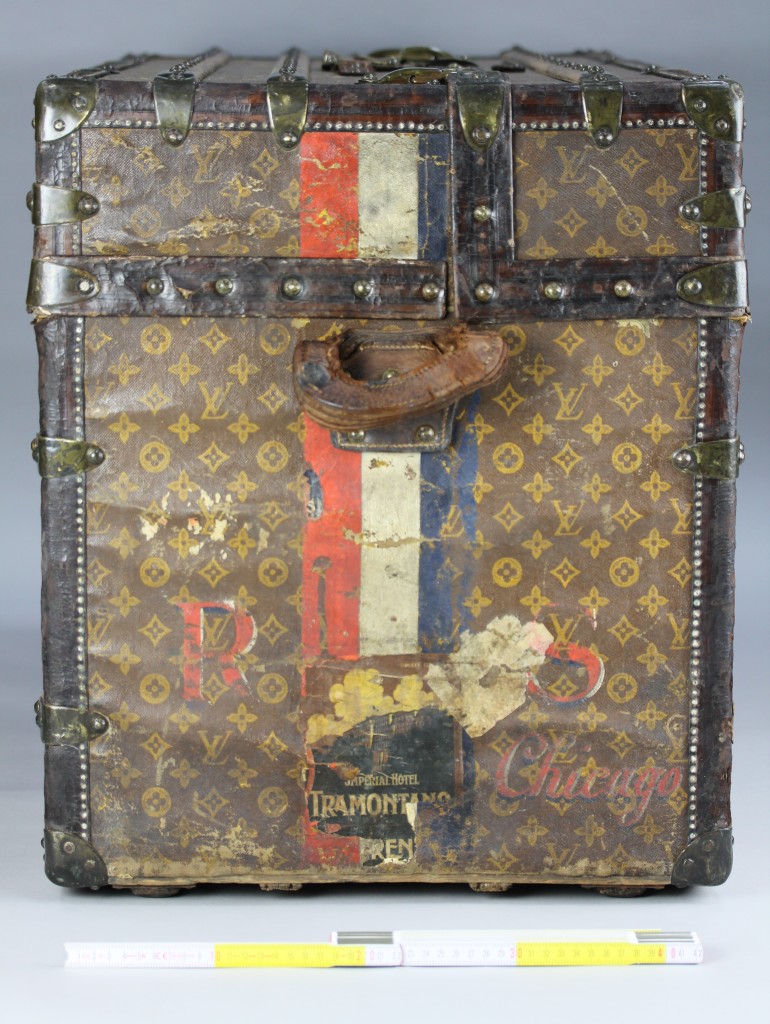

Many of the sites had certain objects they had identified for conservation, and one particularly interesting object was an early 20th century travel trunk made by luxury French fashion company Louis Vuitton. The trunk has quite a history, and had traveled back and forth across the Atlantic a number of times before being donated to the Scottish Maritime Museum in Irvine. When it arrived in the lab at AOC Archaeology for treatment, the trunk was locked, and there was no key! Therefore, in addition to cleaning the painted textile covering and reducing the corrosion on the monogrammed metal studs, I had to disassemble the locking mechanism on the top of the trunk before reassembling it unlocked so that the interior could be accessed in the future. Treating this object, which serves as a fascinating piece of Scotland’s immigration/emigration history, was such a rewarding experience, and can’t wait to see it on exhibition at the Maritime Museum later in the year.

Another interesting object I recently completed working on was a 20th century drafting table, which is now on display in a new exhibition at the Summerlee Museum of Scottish Industrial Life, in Coatbridge. This object was too large, and too heavy, to be uplifted back to AOC Archaeology, and so the treatment was completed onsite at the museum. However, since the timeline for the exhibition was extremely tight, it was decided that reduction of the metal corrosion and any work that may require solvents was to be completed in the store warehouse, with the remainder of the treatment taking place while the table was on display, which provided an excellent opportunity for public engagement with museum guests! It was great to see how many visitors were interested in what I was working on, and what tools I was using, and several older guests even lingered to discuss the differences between conservation and restoration.

Following on from the success of this ‘live action’ conservation, several other onsite projects have been planned for later in the year… stay tuned!

As well as treating objects from each of the museums, my internship has also required me to work with collections managers and curators on discrete projects that will benefit the collections as a whole. These projects have varied across the sites, as there is such diversity in the collections, and it has been a challenging but rewarding experience to create workshops, demonstrations and manuals that are tailored to each museum’s needs: from basic conservation cleaning, to maintenance of outdoor painted objects, and even reducing metal corrosion and the application of metal coatings. One project that I have found particularly engaging has been researching the ethics behind working machinery, a project that pertains to the Verdant Works in Dundee, as they have many machines still in working order that demonstrate the procedure of jute processing. One of the main problems for the Verdant Works has been finding people with the appropriate expertise to maintain and care for the machinery to keep it in working order, an issue which further highlights the need for increased skills training in industrial heritage collections. In response to discussions with curator Mel Oakley I have been working on a set of guidelines and considerations that I hope will come in useful for sites that care for working machinery.

While each Go Industrial member site has their own set of conservation needs, there is one thing they all have in common…hazards! Industrial collections are often liable to contain a variety of hazards, so one of the main projects I have been working on is to create a hazards manual for each site, highlighting what type of hazards they can expect to find, how to identify them, how to safely store them, and how to mitigate them. This work is currently ongoing, but there is a manual rollout expected in December along with a demonstration of equipment and mitigation procedures. One of the most enjoyable aspects of this internship though has been meeting the people volunteering their time at each of the member museums. However, while there is no substitution for the wealth of knowledge that the volunteers working on industrial collections, those with engineering backgrounds, bring to the table, often this comes with a desire to restore objects to working condition, which can often be at odds with the principles of conservation. The hope is that through delivering the workshops and training sessions that have been planned for each site, we can impart a conservation mindset, and help staff and volunteers in their efforts to preserve these collections for future generations.

If you would like hear more about the Powering Our People project, check out my blog on the AOC website, or head to the Go Industrial website to find out more about the member museums!